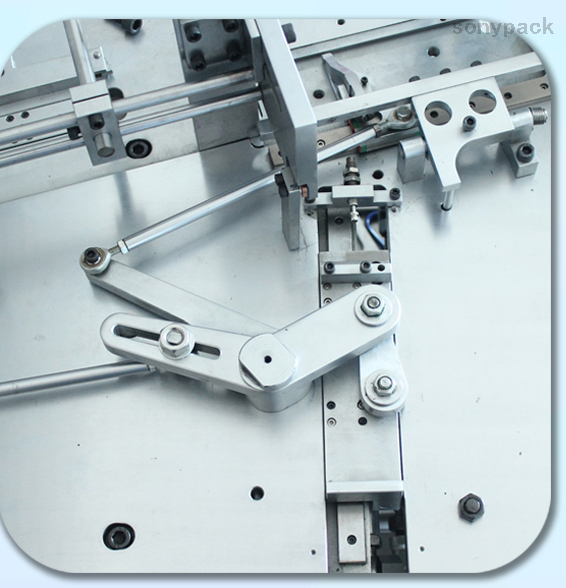

Full Automatic Paper Plastic Hang Tag Threading Machine Buy Tag Threading Machine, paper Tag

Full Automatic Paper Plastic Hang Tag Threading Machine Buy Tag Threading Machine, paper Tag

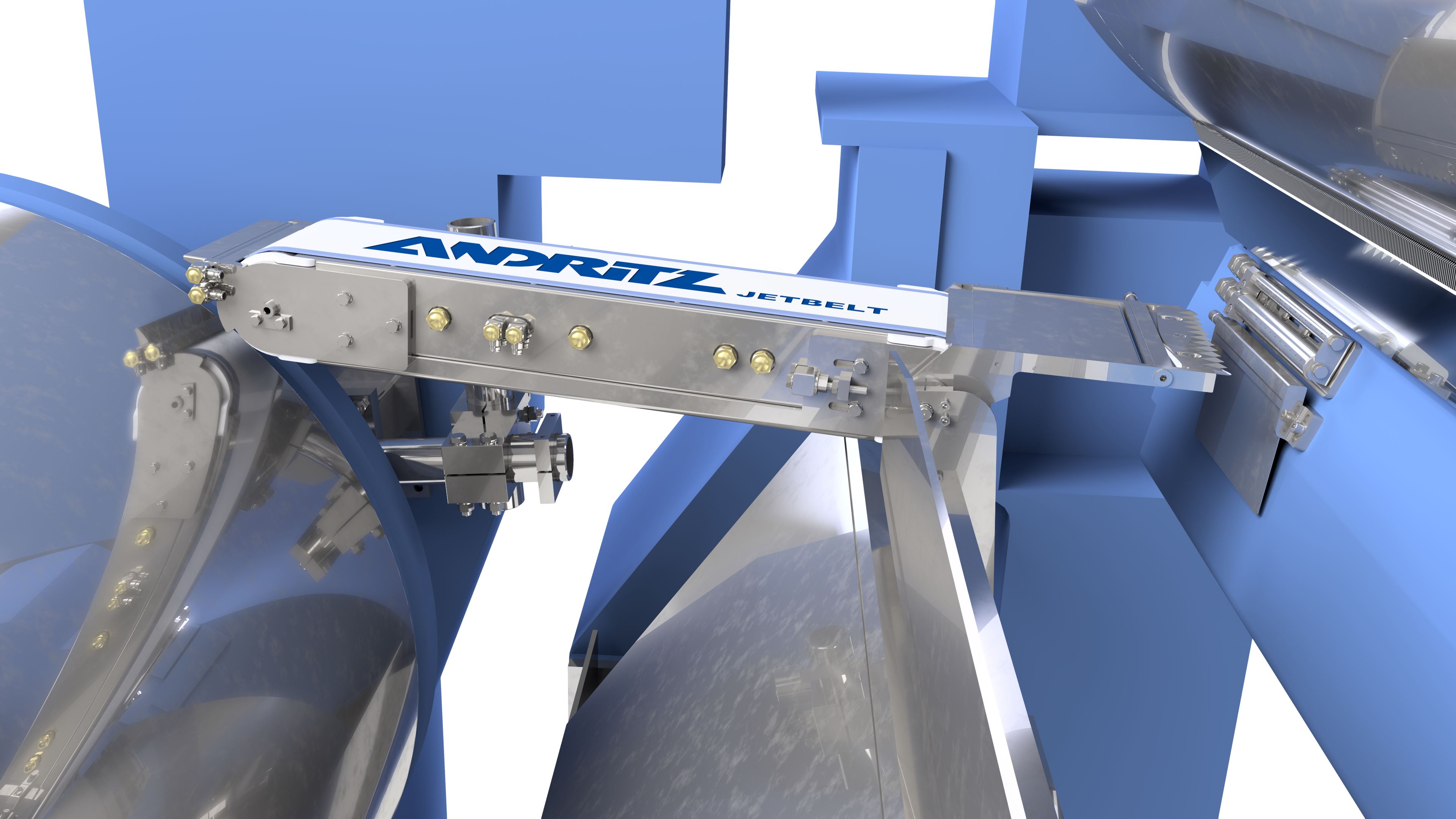

New vertical tensioner. William Kenyon provides market-leading products and technical services that enable customers to maximise the threading performance of their paper and board machines. We have been at the forefront of carrier rope technology since it was first introduced and we remain the only supplier who can offer the complete package of.

High Production Efficiency Paper Mill Equipped The Fullintelligent Paper Threading System For

There are many factors to adjust, set and monitor for efficient tail threading, including air blow and vacuum pressures, conveyor belt speeds and speed differences, tail width and position and tension of the tail. Paper strength, basis weight, moisture, web profile, length of threading distance and machine speed will all affect how the tail.

Tail threading

Amazon Basics 8 Sheet Cross Cut Paper and Credit Card Shredder with 4.1 Gallon Bin, Black. 4.6 out of 5 stars. 211,986. 10K+ bought in past month. $40.94 $ 40. 94.. 8-Sheet StripCut Home Office Shredder, CD/Credit Card Shredder Machine with Overheat Protection, 3.4 Gallons Wastebasket. 4.4 out of 5 stars. 3,704. 3K+ bought in past month.

Threading machine YouTube

Tail Threading Concept and equipment. Toscotec engineers and supplies a complete line of tail threading devices for all paper machine sections regardless of the paper grade and machine configuration. These threading devices are the perfect tool for new machines or to improve the efficiency and safety of an existing line.

Plate type automatic threading rolling machine

Every time a paper or board machine is started after a shutdown or the flowing wet end sheet breaks, it is necessary to rethread the paper sheet from the forming section to the reel of the paper machine.. Our team is looking forward to undertake your new Tail Threading project for your Paper Mill. Contact us: [email protected]. REACH.

THREADING MACHINE 114

Web stabilizers, pocket ventilation and machine geometry modifications eliminate runnability problems efficiently and are often required to ensure fluent paper making process in the press and dryer sections. These maintenance free solutions have a huge impact on drying and energy costs. Especially in high-speed paper machines, the first single.

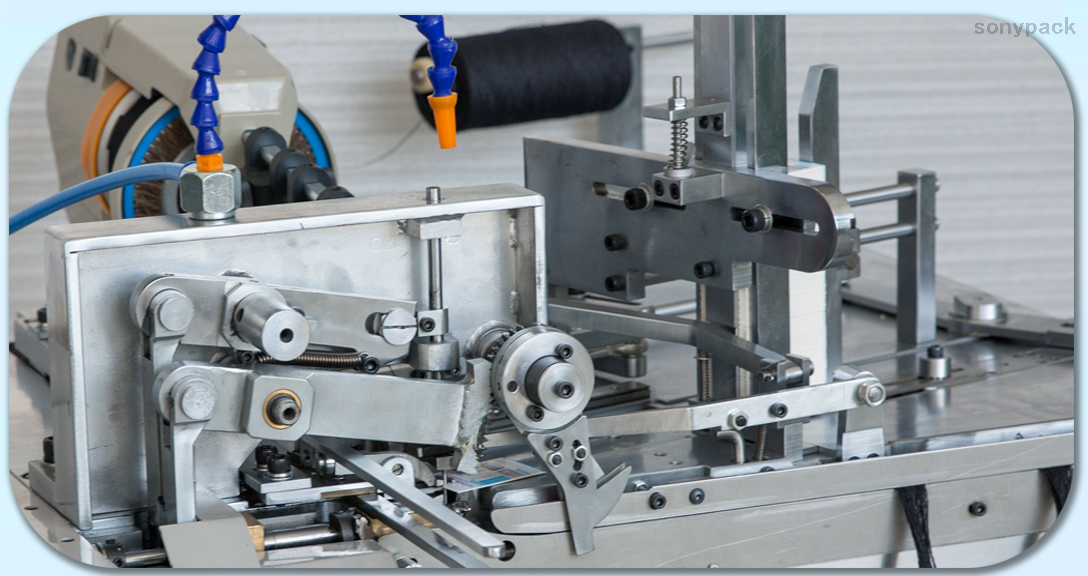

Automatic Book Binding Sewing Machine For Thread Book Sewing from China manufacturer Koten

The experience of more than 175 years of paper machine deliveries allows top performance on any grade. The TurboDryer comes with our reliable threading system either with air or via ropes. Getting the most out of your steam is guaranteed when using our high-class TurboFeeder. Adjustable vacuum level ensures efficient threading.

Threading Threading System with TurboFeeder Bellmer GmbH

Voith Rope Systems provide the reliable sheet threading that the paper industry demands today. Ordering Information / Ordering Form 2 3 The One Platform Concept from Voith was intro-duced to ensure the various paper machine mo-dules, process modules and associated technolo-gy groups maximize the production performance

Powercraft Threading Machine 1/2" 4" PCTM 100 Powercraft

The carrier rope system was introduced over 50 years ago as an answer to the safety and time concerns of threading the paper machine by hand. As machine speeds increased, the need for a faster, more efficient, and safe method of threading was needed; therefore, the "Sheehan" carrier rope system was developed.By DeWitt T. Oliver, General Manager, Carrier Rope and Development, William Kenyon.

Powercraft Threading Machine 1/2" 2" PCTM 50 Powercraft

The embedded IoT sensor can activate the bin's compactor to compress the waste and reduce the volume of plastic and paper so as to maximize the storage capacity. Fill-Level Display . The fill-level of each auto-sorting recycling bin is displayed on the touch screen display and the app. IoT Cloud Platform and App

Manual Book Sewing Machine For Paper Signature Thread Sewing from China manufacturer Koten

After each restart of a paper machine, the paper web must be guided on the proper path though the mahine. Voith offers comprehensive threading process expert.

Deli 9928 mini electric paper shredder 15l office household use high power electric file cutting

PApeR Systems threading is our specialty We're one of North America's top companies specializing in providing end-to-end threading for paper and pulp mills around the world. We focus on robust design, quality equipment manufacturing, and reliable after-sales support. This complete life cycle threading service is what Mantech's Paper Systems are all about and what our Read More "Paper.

Full Automatic Paper Card Plastic Tag Threading Machine China Paper Hangtag Machine and Paper

Tail can be delivered also directly to the dryer section ropes. System can be semi or fully automatic. Suitable for all paper grades with a basis weight below 300 gsm. Minimum air pressure of 5 bar. Web stabilizing and tail threading solutions are safe, reliable and maintenance free resulting in significant benefits.

Threading Threading System with TurboFeeder Bellmer GmbH

It is a tailor-made concept applicable for different dryer section geometries and therefore an excellent tool for upcoming rebuild projects. Paper and board mills report improved operator safety, higher runnability, faster machine speeds and increased production with Runtech Systems' ropeless tail threading and runnability solutions. Videos.

Full Automatic Paper Plastic Hang Tag Threading Machine Buy Tag Threading Machine, paper Tag

Amazon.com: Pipe Threading Machine. RIDGID 15722 Model 300 Power Drive Complete, 57 RPM Pipe Threading Machine and 1/2-Inch to 3/4-Inch, 1-Inch to 2-Inch Universal Alloy Threading Die Heads, Oiler Included. Get Price.

Full Automatic Paper Plastic Hang Tag Threading Machine Buy Tag Threading Machine, paper Tag

Temperature monitoring solution for board and paper machines. Valmet Sheet Temperature Detector is a non-contacting temperature monitoring system. It measures either sheet or dryer surface temperature depending on case-specific circumstances and the operating status of the dryer section. It will improved tail threading and runnability.